The Educator binder jet Development Platform

The Educator

The Educator can be used as either an entry-level introduction to binder-jetting or as a sophisticated development tool to test out new materials or improve process development. The Educator system starts at $100k, including a fully functional binder-jet system with a 60mm build box, curing oven, and de-powdering system designed to capture unused powder for re-use. Designed to fit within a two glove inert box.

The Researcher

The Researcher has the same functionality as The Educator but comes with additional modularity either with a tailored build or a range of add-ons. Starting at $180,000, some of the options include an inert chamber, glove box, drop watcher. We also have a range of powder dispensers from fine talc like powders to grainy metals. We can help you work with various metals, polymers, ceramics or sand. There is also the ability to add or choose from a variety of printheads. Designed to fit within a two glove inert box.

Full Service assistance

PRINT HEAD DOCTOR

As well as a full service technical and application support we offer a range of printhead maintenance tools. Our popular Print head doctor allows you to clean, recover and maintain expensive printheads.

INERT CORP GLOVE BOX

We have a range of options and features including two glove, three glove and four glove inert boxes. The Researcher will fit inside a two glove box but our recommendation is a four glove. Allowing inert storage as well as more elbow room.

THE EDUCATOR IN THE INERT BOX

Designed to fit neatly into an Inert Corp two glove system. Note the green oven, de-powdering and powder reclamation are all inside the inert box.

MATCHED RAPIDIA CONFLUX 1 FURNACE

A great starter furnace matched to the Educator build box. Suitable for most metal powders upto 1400 °C / 2550 °F

Hot zone dimensions 9.64” ID by 12” long

IMAGEXPERT JETXPERT JR DROPWATCHER SYSTEM

IMAGEXPERT JETXPERT JR DROPWATCHER SYSTEM

The compact JetXpert Jr from the well regarded ImageXpert dropwatcher is well paired with The Educator platform. A powerful printhead dropwatcher installed prior to shipping. JXJRVIZ JetXpert Jr dropwatcher system available with several software packages

What does the AM industry mean by Open architecture?

“An open-architecture system becomes a tool for more than just making parts, but also for making advances in the industry.”

There are a number of claims of an open architecture recently. Here is a check list from a great reference article by Ty Pollak of ARCTOS

B-jetting has designed their systems from the ground up with the modularity of a Swiss army knife, ticking all the boxes.

All backed by a best in class technical and application support.

✅ OPEN ARCHITECTURE

✅ OPEN CONFIGURATION

✅ OPEN CONFIGURATION

Truly open-architecture systems allow freedom to modify, develop, and/or integrate hardware or software components. Ideally, the platform should be designed with openness in mind from the outset.

✅ OPEN CONFIGURATION

✅ OPEN CONFIGURATION

✅ OPEN CONFIGURATION

The modularity of the system should allow configurations based on project or application needs. Reconfiguration can be accomplished by the machine manufacturer or a third party.

✅ OPEN MATERIALS

✅ OPEN CONFIGURATION

✅ OPEN PARAMETERS

There should be no restrictions on materials or sources, other than conformance to minimal specifications to ensure operability. There should be no limitations to material sources.

✅ OPEN PARAMETERS

✅ OPEN PARAMETERS

✅ OPEN PARAMETERS

The capability to dial in their own processing parameters. Also having insights into the presets for any pre-loaded materials recipes.

✅ OPEN SENSING

✅ OPEN PARAMETERS

✅ OPEN MAINTENANCE

Open additive systems should place no restrictions on integration of third-party sensors and provide all raw data for integrated sensors.

✅ OPEN MAINTENANCE

✅ OPEN PARAMETERS

✅ OPEN MAINTENANCE

An open platform should empower not shackle users maintaining their system. Users should have the option to make their own minor repairs and replacements.

The standard educator & modular Researcher

OUR VISION

At b-jetting, we envision a world where engineering solutions are sustainable, innovative, and accessible to all.

Our goal is to create an environment that speeds up 3d research and development.

THE BUILD BOX

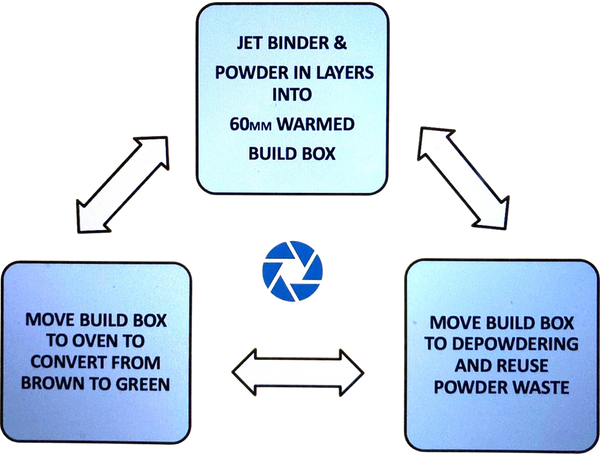

The build box moves from the Z axis build box to the green oven to the de-powdering area

THE FIVE SLOT SYSTEM

The five slot system is standardized on The Educator as shown above.

The Researcher modular slots can be configured for your program needs.

The educator platform users

BINDERJET Introduction

BINDERJET Introduction

BINDERJET Introduction

A low cost, out-of-the-box learning tool to explore binderjet or to train new employees

Research

BINDERJET Introduction

BINDERJET Introduction

Focus on your research not on building the test bed. The modular slots allow you to tailor the platform to a wide range of needs

POWDER EVALUATion

BINDERJET Introduction

printhead EVALUATion

Small batch lab evaluation so you can create samples or study powder flow characteristics

printhead EVALUATion

POINT OF NEED MANUFACTURING

printhead EVALUATion

Evaluate different printheads side by side while developing your unique process

development

POINT OF NEED MANUFACTURING

POINT OF NEED MANUFACTURING

Modular, IO addressable slots so you can create your own parameters or develop new components

POINT OF NEED MANUFACTURING

POINT OF NEED MANUFACTURING

POINT OF NEED MANUFACTURING

Sturdy, field transportable, 3D binderjet system all in one box for point of need evaluation

The build box

- The Educator has a 60mm removable build box which circulates between build area, the oven for brown to green parts and the depowdering station.

- The depowdering system draws a vaccum over the build box and collects the powder into a hopper for reuse.

- All three zones are built into the printer so it will easily fit into a small Inert box or glove box.

- The Researcher has a choice of build boxs; a 60mm cube, 125mm x 60mm 35mm or a 30mm cube with a compact hopper for precious metals.

The five slots

- There are five modular slots with a range of powder handling components designed around various flow characteristics from a powdery talc consistency for something like a low flow ceramic to a rough, grainy metal powder.

- We can also design a proprietary powder handling system for a powder with unique powder flow characteristics that you can use on The Educator.

The open architecture

- The Educator platform has a standard configuration this allows you an out of the box binderjet system for say a standard MIMs 316 Steel.

- But because of the five modular slots with open IOs you can adjust and capture parameters on a module or even design a powder handling system to plug into slots.

- Binderjet allows you to explore materials from metals, alloys and ceramics. The parts are all grounded so you open to play with something like a static prone polymer.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.